CNC devices have revolutionized the production sector with their precision, rate, and flexibility.

We will discover what CNC makers are, exactly how they work, the various kinds offered, and the advantages of using them.

Furthermore, we will offer ideas on picking the best CNC machine for your needs and where to find them offer for sale.

Whether you're looking to raise production effectiveness or boost product top quality, CNC makers can assist take your company to the next degree.

Key Takeaways:

CNC machines supply increased precision, higher production speed, adaptability in layout, and minimized labor expenses.

When choosing a CNC equipment, consider your manufacturing demands, budget, research study brand names and models, and check out evaluations and referrals.

CNC makers can be discovered offer for sale directly from suppliers, online marketplaces, used machinery dealerships, and auctions and liquidations.

What Are CNC Machines?

What Are CNC Machines?

CNC devices, or Computer Numerical Control machines, are automated tools utilized in the manufacturing market to precisely control machining processes with computer software application, making them important tools in modern assembly line.

These equipments have actually revolutionized the method items are manufactured, allowing for high levels of precision and effectiveness that were previously unattainable. The historic growth of CNC makers go back to the mid-20th century when they were first presented for armed forces applications and later on embraced by exclusive markets. Today, CNC makers play a important duty in industries such as vehicle, aerospace, electronics, and medical tools.

Examples of CNC tools consist of CNC milling devices, lathes, routers, grinders, and plasma cutters. Each sort of CNC equipment is specialized for specific applications, offering versatility and accuracy in various making procedures.

How Do CNC Machines Work?

CNC devices function by making use of computer software application to regulate the activity of tools and equipment, making it possible for accuracy manufacturing procedures such as milling, transmitting, and cutting.

This modern technology allows for intricate layouts and very exact outcomes due to the systematic nature of operations executed by CNC makers. The electronic control not only boosts performance yet likewise lowers human error in the manufacturing process.

For example, in CNC milling makers, the programmed guidelines determine the course and depth of the cutting device, causing consistent and repeatable production runs. Similarly, CNC routers are widely made use of in woodworking and metalworking sectors for jobs like inscription, cutting, and shaping various products with exceptional information and speed.

What Are The Types Of CNC Machines?

There are different sorts of CNC devices, each created for particular machining tasks, consisting of CNC mills, CNC lathes, CNC routers, and CNC waterjet cutters, every one of which take advantage of computer-controlled precision to improve producing efficiency.

CNC Mills

CNC mills are flexible machining devices made use of to carry out various milling operations with high accuracy, making them optimal for both facility and straightforward reducing jobs in various industrial applications.

Their accuracy is unrivaled, enabling complex layouts and specific cuts with exceptional precision. CNC mills can take care of a wide range of materials, from steels like light weight aluminum and steel to composites and plastics, showcasing their adaptability.

Among the key benefits of using CNC milling equipments is their capability to create constant outcomes and repeatability, important for mass production in industries such as vehicle, aerospace, and electronics.

These equipments are customized to fulfill specific production requirements and can be tailored with numerous tooling choices based on the task needs, making them very adaptable.

CNC mills are conveniently offered available from a selection of suppliers, providing various sizes and setups to suit diverse production demands.

CNC Lathes

CNC lathes are crucial devices in the production sector for carrying out exact transforming operations, allowing for the development of balanced, cylindrical components with computer-controlled procedures.

These innovative equipments enable the manufacturing of elaborate components with high precision and repeatability, making them excellent for sectors such as aerospace, automobile, and clinical.

CNC lathes provide a wide range of functions, including facing, exploration, threading, and grooving, making sure convenience in producing procedures. Whether you are aiming to develop prototypes or mass-produce parts, CNC turrets give effectiveness and uniformity. Investing in a CNC lathe for sale not only boosts efficiency but additionally improves the top quality and precision of your outcome, causing cost financial savings and competitive advantages in the market."

CNC Routers

CNC routers are extensively utilized for reducing and forming materials such as wood, plastic, and metal, providing high precision and adaptability for numerous commercial and creative applications.

These devices make use of computer system numerical control technology to comply with particular design instructions and produce intricate cuts and forms with phenomenal accuracy. CNC routers locate substantial usage in industries like woodworking, furniture manufacturing, signs production, and prototyping due to their capacity to execute intricate designs consistently. They are also utilized in universities for teaching purposes.

For those looking to discover the acquisition of a CNC router available for sale, vital factors to consider consist of the maker's size, cutting location, pin power, control system, and software application compatibility. An evaluation of desired use and budget plan constraints is vital in picking the most suitable CNC router for details needs.

CNC Plasma Cutters

CNC Plasma Cutters CNC plasma cutters are specialized devices utilized for cutting through electrically conductive products with high accuracy and rate, making them useful possessions in steel manufacture sectors.

These cutters function by routing a high-speed jet of ionized gas towards the metal surface, while an electric arc is created that thaws the metal. The accuracy of the cutting is regulated by computer system numerical control (CNC) innovation, which makes sure detailed designs are properly duplicated.

Among the vital benefits of CNC plasma cutters is their capability to puncture various thicknesses of steel, varying from slim sheets to thick plates, with very little heat-affected areas. This results in tidy cuts, decreasing the requirement for more handling and minimizing product waste.

There are different kinds of CNC plasma cutters offered, consisting of handheld, robotic, and mobile systems, each dealing with particular industrial requirements. Handheld cutters are frequently utilized for onsite repair services and upkeep, while robotic systems are favored for massive manufacturing in industries such as auto, aerospace, and building and construction.

CNC Laser Cutters

CNC laser cutters use focused laser beam of lights to cut and inscribe products with unparalleled precision, making them perfect for elaborate layouts and premium coatings.

CNC laser cutters run based on the principles of using a high-powered laser light beam that is focused through a collection of mirrors and lenses to precisely cut through numerous products. This innovation permits complex and in-depth designs, as it can achieve very great cuts with high precision. The versatility of laser cutting is evident in its capacity to deal with a wide variety of materials, including metals, plastics, timber, textiles, and extra.

CNC 3D Printers

CNC 3D printers are transforming production by enabling the creation of three-dimensional things with additive procedures, offering unparalleled adaptability and technology in style.

These innovative makers can creating elaborate and complicated structures with high accuracy and accuracy, making them necessary tools in the prototyping and manufacturing process. The CNC 3D printers are flexible, able to work with a wide range of products such as plastics, steels, porcelains, and even bioinks, allowing for the manufacturing of varied items across different markets.

CNC Waterjet Cutters

CNC waterjet cutters utilize high-pressure streams of water blended with rough products to cut through various substances, offering a cold-cutting process that lessens material contortion and heat-affected areas.

This modern technology is specifically advantageous for cutting fragile or heat-sensitive products like foam, rubber, and plastics, where traditional reducing techniques could bring about distortion or thermal damages. By specifically controlling the waterjet's stress and rate, these devices provide precise cuts with smooth edges, lowering the demand for additional completing procedures.

The convenience of waterjet cutting machines allows them to be utilized throughout many sectors, including aerospace, vehicle, and style. Due to the enhancing popularity of this cutting technique, there are various waterjet cutting makers up for sale that deal with various manufacturing volumes and cutting demands.

What Are The Benefits Of Using CNC Machines?

The advantages of using CNC equipments are numerous, consisting of boosted accuracy, greater production rates, flexibility in layout, and decreased labor costs, every one of which contribute to boosted effectiveness and productivity in producing procedures.

Raised Precision

Raised accuracy is among the main benefits of CNC equipments, allowing for the production of very precise and constant parts that meet strict quality criteria.

Via the application of computer-controlled procedures, CNC devices are able to accomplish remarkable levels of accuracy in producing procedures. These equipments follow programmed guidelines to carry out complex jobs with extraordinary precision, making them important in industries such as aerospace, auto, and clinical devices.

Industries that require facility and comprehensive elements considerably benefit from CNC modern technology. The aerospace industry depends on CNC equipments to generate precise parts for aircraft engines and structures, making certain security and performance. In the clinical field, CNC machining plays a important duty in creating elaborate medical tools and prosthetic tools that call for absolute accuracy for optimal functionality.

The high precision accomplished through CNC procedures dramatically improves product quality and uniformity. Manufacturers can recreate similar parts with marginal variability, bring about enhanced overall item performance and dependability. This level of consistency is particularly vital in industries such as electronics and protection, where even small inconsistencies can have severe effects.

Greater Production Speed

Greater Production Speed CNC devices significantly boost production rate by automating complex machining processes, lowering the moment called for to manufacture parts and raising overall throughput.

This better efficiency not just increases the production process however also simplifies operations in industries such as aerospace, vehicle, and electronic devices.

For example, in the auto market, the quicker manufacturing allowed by CNC devices allows manufacturers to fulfill limited due dates for brand-new car versions, eventually decreasing time-to-market and raising competition.

Similarly, in the aerospace industry, the ability to swiftly generate intricate elements brings about faster assembly of airplane, enhancing lead times for aircraft production and maintenance.

Flexibility In Design

The flexibility of CNC devices in layout enables makers to produce intricate and intricate parts that would be challenging or impossible to create with standard machining approaches.

This layout versatility supplied by CNC machines is especially beneficial when handling complex geometries, where accuracy is paramount.

CNC equipments enable personalization on a level that was formerly unattainable, giving manufacturers the flexibility to trying out unique sizes and shapes.

This impact on product innovation and development can not be downplayed, as it opens a world of possibilities for developing sophisticated products that push the limits of traditional manufacturing methods.

Minimized Labor Costs

Minimized labor expenses are a significant advantage of CNC makers, as they automate numerous manual jobs, decreasing the demand for competent labor and reducing total production expenses.

By improving the production procedure, CNC makers not only lead to expense financial savings however likewise improve performance and precision in manufacturing. This automation not only lowers human mistake however likewise improves performance, enabling faster turn-around times on orders.

Producers can reapportion their labor force to even more strategic jobs that require human imagination and problem-solving abilities rather than recurring manual labor. This change in labor emphasis can bring about innovation and better items, ultimately boosting the competitive edge of the firm in the market.

Just how To Choose The Right CNC Machine For Your Needs?

Selecting the ideal CNC device for your demands entails a thorough evaluation of your manufacturing needs, spending plan factors to consider, research on different brand names and models, and seeking evaluations and suggestions from sector experts.

Identify Your Production Needs

Determining your production requires is the first step in picking the right CNC machine, as it makes sure the equipment you select aligns with your certain production needs.

Examining manufacturing requirements involves a thorough evaluation of the types of materials that will be processed, the necessary production volume, and the degree of precision crucial for your completed items. By comprehending these key variables, you can successfully match CNC tools capacities to your details needs, thereby making the most of performance and guaranteeing ideal performance in your manufacturing procedures.

Consider Your Budget

Considering your spending plan is important when choosing a CNC equipment, as it helps limit options and guarantees you buy equipment that uses the most effective value for your monetary strategy.

One crucial element to include in your budget plan preparation for a CNC maker is the preliminary costs. This covers the purchase cost of the machine itself, any type of necessary tooling, and installation costs. Continuous upkeep expenditures should be represented. Routine upkeep not just lengthens the life expectancy of the maker however additionally stops pricey repair work down the line.

When trying to find affordable alternatives, take into consideration acquiring utilized or refurbished CNC equipments from trustworthy vendors. This can substantially lower the preliminary financial investment while still offering reputable devices. An additional pointer is to explore renting choices, which can expand the costs in time and often include maintenance services in the bundle.

Research The Brands And Models

Research study The Brands And Models

Researching the brand names and designs of CNC machines is essential to recognize reputable and trustworthy alternatives that meet your production needs and top quality requirements.

When exploring the world of CNC makers, thorough study is crucial to ensuring you buy a system that aligns with your particular requirements. One important aspect to consider is reviewing the features provided by various brand names and versions. Compare specifications such as cutting dimensions, spindle speed, and tool capacity to figure out which machine can finest handle your jobs. In addition, checking out the efficiency examines from market professionals and present customers can supply valuable insights right into the dependability and performance of each CNC maker.

Read Reviews And Ask For Recommendations

Reviewing reviews and asking for recommendations from industry specialists supplies valuable insights right into the performance and reliability of different CNC machines, assisting in making informed purchasing decisions.

By using the know-how of others, prospective buyers can obtain extensive expertise about the particular features, pros, and cons of different CNC models. This direct information can help them evaluate whether a particular equipment straightens with their production needs and spending plan. Peer guidance and real-world experiences provide a sensible expectation that goes beyond item specs, permitting individuals to anticipate any possible challenges or benefits related to a specific CNC equipment investment.

Where To Find CNC Machines For Sale?

Searching for CNC machines up for sale can be achieved through different channels, including straight buy from makers, on-line markets, made use of machinery dealerships, and auctions or liquidation occasions, each offering one-of-a-kind benefits and factors to consider.

Straight From Manufacturers

Purchasing CNC makers straight from makers makes certain access to the most up to date models, service warranty coverage, and trusted client support, making it a favored option for several buyers.

When getting directly from suppliers, clients often benefit from affordable pricing due to the elimination of intermediaries. Furthermore, they have the advantage of direct interaction with the professionals that made and generated the equipments. Brand names like Haas, Mazak, and DMG Mori are renowned for their innovative CNC technology and comprehensive after-sales solutions.

These makers supply a large range of equipments catering to different industries, from little desktop computer versions for enthusiasts to heavy-duty industrial devices for large manufacturing. By procuring directly from trusted brand names, clients can be ensured of the quality, toughness, and accuracy of the CNC equipments they buy, inevitably leading to enhanced performance and performance in their operations.

Online Marketplaces

On-line markets provide a practical system to surf and compare a wide variety of CNC machines up for sale, providing affordable prices and individual testimonials to help in decision-making.

When navigating on-line markets for CNC equipments, it is essential to make note of numerous aspects to make an notified purchase. You can make use of the search filters to limit choices based on your particular demands such as machine type, size, and attributes.

Contrasting rates across various listings can aid you locate the most effective deal while guaranteeing you remain within your spending plan. Reviewing individual testimonials can provide important insights into the performance and dependability of the maker, assisting you assess its viability for your requirements. Constantly prioritize buying from reliable sellers with favorable comments to guarantee a safe and safe and secure purchase.

Made Use Of Machinery Dealers

Made use of equipment suppliers use a cost-efficient choice for obtaining CNC makers, providing access to pre-owned devices that has actually been checked and refurbished for reputable efficiency.

Among the vital advantages of purchasing from these suppliers is the potential for significant expense financial savings compared to buying brand-new machinery. This can be particularly helpful for companies seeking to expand their operations without the huge upfront financial investment. Many utilized equipment suppliers provide a large option of well-maintained tools from credible brand names, offering buyers the possibility to select from a variety of choices that match their details requirements.

Public auctions And Liquidations

Public auctions and liquidations existing chances to buy CNC machines at competitive costs, usually featuring a broad choice of devices from companies that are upgrading or shutting operations.

Participating in these occasions can be an amazing method to obtain high-grade machinery for a portion of the cost. When taking into consideration bidding process at auctions or liquidations, it's essential to investigate the devices in advance, inspect them thoroughly when possible, and established a budget to stay clear of overbidding. The benefit of acquiring via auctions is the potential to protect equipment at below-market prices due to the affordable nature of bidding process.

Frequently Asked Questions

What are CNC makers used for?

CNC equipments are used for a variety of manufacturing processes, such as reducing, exploration, and shaping products like steel, timber, and plastic. They are generally utilized in industries such as automobile, aerospace, and electronics.

What are the benefits of using a CNC maker?

Among the primary advantages of using a CNC maker is its accuracy and precision. Considering that the machine is controlled by a computer, it Stratasys 3d Printer Price can generate highly detailed and constant outcomes. In addition, CNC machines can increase manufacturing rate and efficiency, liberating time for various other jobs.

Exactly how do I select the best CNC machine for my needs?

When thinking about acquiring a CNC machine, variables to consider consist of the kind of product you will be dealing with, the size and intricacy of your jobs, and your budget. It is necessary to research study and compare various designs and brand names to locate the very best fit for your certain demands.

What are some typical types of CNC machines?

Some common kinds of CNC machines consist of lathes, mills, routers, grinders, and plasma cutters. Each kind is made for details applications and materials. It is necessary to choose the best kind of CNC device for your meant usage.

Are there any kind of safety preventative measures I should take when making use of a CNC device?

Yes, it is essential to always follow security guidelines when operating a CNC device. This includes putting on protective equipment, such as gloves and shatterproof glass, and correctly protecting your workpiece. It is likewise essential to routinely keep and inspect the maker to ensure risk-free procedure.

Where can I discover CNC devices offer for sale?

CNC equipments can be bought from numerous sources, such as makers, representatives, and online merchants. It is very important to look into the seller's online reputation and client testimonials prior to making a purchase. You can likewise discover secondhand CNC machines available for sale from resellers or with online markets.

Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Bug Hall Then & Now!

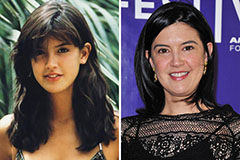

Bug Hall Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!